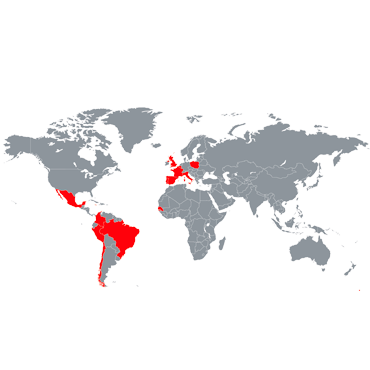

EPC company. We recently learned that Wiki-Solar ranks us the number five EPC company in the world and number six in operation and maintenance. This is how it appears in its latest ranking of leading utility-scale solar construction partners. Thanks to our team and the trust of our customers, we occupy top positions among the best companies in the world: the number one French, the number two European, and the number two company worldwide in terms of installed power and O&M since 2019. The Eiffage Energía Group carries out all its national activity through a consolidated presence, with over 50 branch offices distributed throughout the territory. Internationally, we are one of the most prominent Spanish companies in the sector. Our process of internationalisation began in 2008 in Europe, with the turnkey construction of the Amareleja photovoltaic solar plant in Portugal. It subsequently became consolidated with the construction of the Pawlowo wind farm in Poland in 2012. This project was followed by many others under the “Eiffage Export” model in the United Kingdom, France, Italy and Senegal, among other countries. In 2013, we began our expansion in LATAM, with electricity infrastructure projects in Brazil and the Javiera solar photovoltaic plant in the Atacama Desert in Chile. In 2014 in Mexico and in 2017 in Jamaica, with the construction of Paradise Park, the largest solar plant in the Caribbean. We currently operate with international subsidiaries in Chile, Peru, Mexico, Jamaica and Colombia.

Renewable energies

Renewable energies are a fundamental part of the company’s different lines of business. A line of business where we work as an EPC company to offer clients the best service. For this purpose, we place our technological capabilities at their disposal at any phase of a wind or photovoltaic project. From the engineering, design, construction and operation phases to the maintenance phase. A recent example is Elawan Energy’s award of the EPC contract for construction of the Campanario photovoltaic park in Spain, which we are currently completing. With the “turnkey” or EPC method, the traditional three-way relationship between client, engineer and contractor disappears. That process is replaced by a single relationship between the client and the contractor. A connection in which the latter, in addition to its traditional functions in the supply of equipment, construction and commissioning, also assumes responsibility for project engineering. This means that at Eiffage Energía we are able to put our technological capacity at the service of customers for any phase or a wind or photovoltaic project. We offer a global service, which includes civil works, electromechanical works and all the electrical infrastructures required for the evacuation of the power generated. In terms of numbers, we are one of the companies that has built the most renewable facilities in Spain: 90 wind farms, with a total installed capacity of more than 3.2 GW, and 80 photovoltaic plants, with more than 3.5 GW of capacity.

The energy transition as a strategy

We are responsible for around 80% of the Eiffage Group’s renewables activity worldwide. We avoid the emission of more than 13 million tonnes of CO2 into the atmosphere per year, contributing to the energy transition as a strategy to achieve carbon neutrality no later than 2050. Eiffage Energía also has a new and innovative Control Centre, located at the company’s headquarters in Albacete. The solar plants maintained by the Operation and Maintenance (O&M) department are controlled from this centre. Specifically, assets are managed. From the operational point of view, where the monitoring and control task requires a swift reaction, as well as from a preventive and predictive point of view. In this case, the behaviour of each installation analysed in greater depth.

Operation and Maintenance

Eiffage Energía has a strong commitment to the operation and maintenance of facilities, power generation plants and industrial plants. We carry out operation and maintenance functions in power generation and industrial plants. In the latter, with a 24/7 control centre, we specialise in panel cleaning, land clearing, drone-based thermography service, predictive analysis with machine learning methods, maintenance of LV/MV electrical installations and instrumentation, work on production lines, and in the maintenance of mechanical installations.

Over 300 qualified technicians

We currently have more than 300 technicians qualified to the highest industry safety standards working on all types of inverter, tracker and high-voltage technologies. This positions us as one of the companies with the most technical specialists available to our customers to address situations related to the operation and maintenance of their facilities. In addition, the quality of the work teams, tools and specialised services available to us are noteworthy. In this regard, the high-voltage transformer testing and testing service should be highlighted; Electrical Protection Testing and Trials Service in Substations; and the company’s own drone-based aerial inspection service. With the latter, we inspect high-voltage overhead lines; Generation facilities; Substations; or wind turbines, among others. For example, Iberdrola recently awarded us the framework agreement for maintenance services for solar farms owned by Iberdrola Renovables in Extremadura, and we have just been awarded the three-year O&M contract for Acciona Energía’s high-voltage facilities in Castilla-La Mancha. Ultimately, our customers want a plant that is competitively priced, has maximum efficiency, and that can be connected as quickly as possible. That is what we currently offer at Eiffage Energía, and that is why they place their trust in us.

From BOS to EPC

We have gone from performing BOS to being a reference in EPC work in the photovoltaic sector, with significant growth. As a result, we are positioned as a leading EPC company in the world. In addition to our existing procurement and construction resources, we have been able to develop our engineering capabilities. This enables us to make the best use of the surface areas available for the construction of the plants, offering our customers an optimised LCOE (level cost of energy). And lastly, we add another “C”, for “commissioning”, to complete the acronym EPC+C. This is what sets us apart from our competitors. We have the capacity to carry out the tests and procedures for our clients to obtain the COD (commercial operation date), which allows them to bill for the energy discharged to the grid.