Eiffage Energía Sistemas has now produced its first kilograms of renewable H2. We achieved this milestone through a pilot project involving the production of renewable hydrogen via the electrolysis of water. This pioneering project has recently been categorised as R&D.

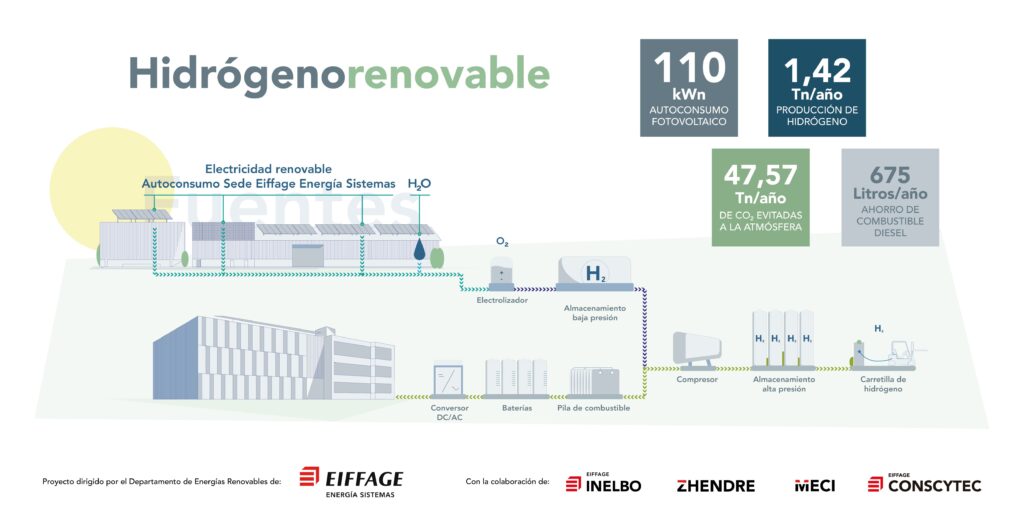

After completing rigorous pre-commissioning tests, we have commenced the production of renewable hydrogen using water and electricity generated from a 110kWp solar self-consumption system.

The pre-commissioning tests included checking the strength/leak tightness of the lines, commissioning and configuring the main electrical equipment, and control loop tests on instrumentation and test circuits with nitrogen.

At present, the AEM (Anion Membrane Exchange) electrolyser is operating at full capacity to fill the low-pressure storage tank. The gas will then undergo compression to 500 bar, will subsequently be stored in the high-pressure tank.

Next phases

The next step to complete the testing and commence operations is to dispense the hydrogen to a 5-ton forklift that will be used in our facility’s warehouse.

It’s worth noting that this pilot project, aimed at promoting the green transition through renewable hydrogen production, is located at our headquarters in Albacete.

We are adding a new 126kWp facility to our existing 58kWp self-consumption photovoltaic system. This will provide an electrolyser with treated water and renewable electricity. Of the 126kWp, 45kWp will be used for this project. The remainder will be distributed to be consumed by the headquarters.

Various uses of renewable H2

The renewable hydrogen that is produced will have two uses:

We will store some of it at 35barg pressure to be compressed through a piston compressor from 35barg to 500barg. The compressed hydrogen will be stored in high-pressure cylinders for fuelling a 5-tonne warehouse forklift truck. A fuel cell powered forklift truck driven by an electric motor.

Electrolyser inverter process

In parallel, when the high-pressure storage tank is completely full and the forklift does not need to be refuelled with H2, we will use the stored hydrogen to run the electrolyser’s inverter process. We will run it through a PEM technology fuel cell which, in combination with O2, will generate electricity. And this electricity will be consumed by the headquarters as if it were an energy storage system, or as a UPS providing an auxiliary service.

Everything will be controlled by a system that will synchronise the automatic operation of the whole installation as well as its component equipment: process equipment; electronics, automatic values; H2 sensors; H2 analysers; and instrumentation.

This project is an example of the synergies that exist between Eiffage Group companies, such as Zhendre Meci, Inelbo (SGA), Conscytec and Eiffage Energía Sistemas.

News in the media: