Innovation and Health Awards. Eiffage Energía Sistemas emerged as one of six finalists in the Large Company category at the VIII Edition of the Mutua Universal Innovation and Health Awards, securing a runner-up position. These awards honour innovation for the benefit of people.

Juan Pablo Valverde Romero, Health and Safety Director, and Francisco López Labrador, Quality and Environment Director, accepted the second prize at a ceremony in the Casino de Madrid.

SecondArmS

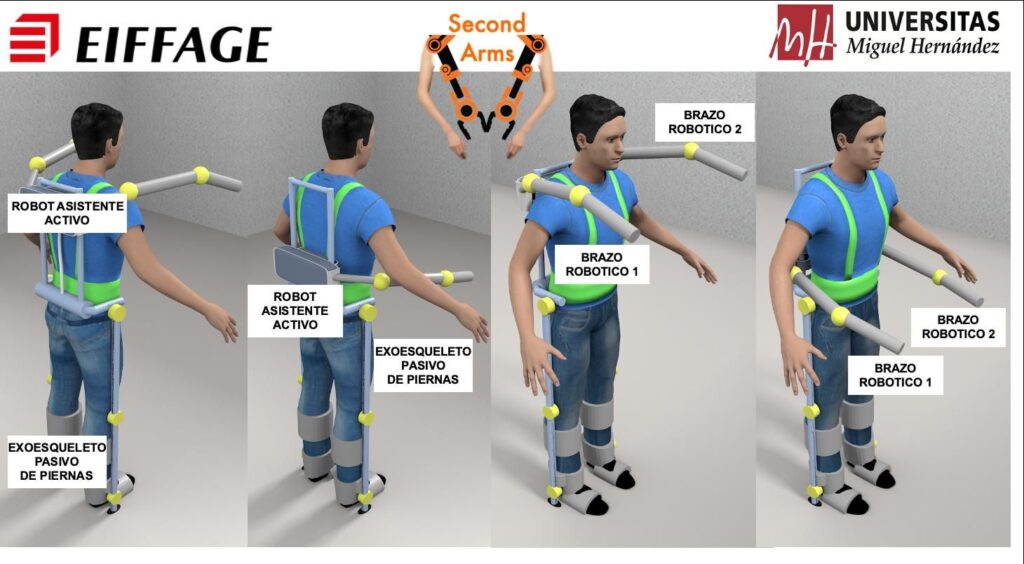

Eiffage Energía Sistemas participated in the awards with their project SecondArmS: robotic arms for installation and maintenance tasks to help minimize the risk of overexertion injuries. This project was developed to eliminate or reduce musculoskeletal disorders (MSDs), which are often caused by manually moving heavy loads, maintaining poor posture, and performing repetitive movements during the installation and maintenance of industrial installations.

No commercial option on the market

Eiffage Energía Sistemas’ Joint Prevention Service has recently observed an increase in sick leaves attributed to MSDs. In response to this, Eiffage Energía Sistemas sought a market-based solution involving portable robotic systems that could act as secondary arms to assist operators in installation and maintenance tasks, but they found no existing commercial options that fulfilled their specific requirements.

Consequently, the company embarked on developing a portable, bimanual robotic system, complemented by a passive exoskeleton-like structure for the lower limbs, intended for workplace use. This device is designed to assist users in avoiding fatiguing or painful postures during industrial maintenance work, particularly for tasks performed above head height.

The implementation of the SeconDArmS system in the operation and maintenance of industrial systems and equipment yields benefits for both the user (worker) and the company.

Benefits for health and work productivity

At the user level, the possibility of using a robotic assistance system offers significant benefits. On one hand, it reduces the risk of workers suffering MSDs by avoiding repetitive movements with heavy loads; on the other hand, utilizing robotic and augmented reality systems enhances the worker’s specialization, enabling them to perform more tasks in less time while improving their training and employability.

Additionally, the SeconDArmS system provides an industrial solution to the significant demographic challenge posed by an ageing workforce. The use of these robotic systems in carrying out physically demanding tasks enables workers to maintain productivity in their roles, regardless of age, while minimizing health risks.

Benefits for the company

At the company level, the productivity benefits of the SeconDArmS system are remarkable. Such benefits are not limited to a reduction in sick leave caused by MSDs among employees. Implementing bimanual and wearable robotic systems at the enterprise level enhances productivity, quality, and safety in the application area, addressing various business needs, including:

– Improved product quality and uniformity, better health and safety in the workplace, and increased production rates.

– Greater flexibility in industrial processes.

– Space savings in storage plants and shortening of lead times.

– Increased competitiveness of the company.

– Adapting to demographic shifts in the workforce.

– Training of specialised personnel.

Different challenges

The project has faced and overcome several challenges, such as:

– Developing a lightweight, safe, and reliable bimanual robotic system to aid in performing tasks in industrial maintenance environments.

– Developing an advanced human-machine interface.

– Researching and developing a device control system that interprets the user’s intention: device in free mode; remote controlled; controlled by user intention detection; and supervised. – The SeconDArmS system has undergone validation in simulated real industrial maintenance environments within our facilities.

In this edition of the Mutua Universal Innovation and Health Awards, the participating companies demonstrated through their best practices their commitment to the health and safety of their workers. To achieve this, as Eiffage Energía Sistemas has exemplified, they have implemented various multidisciplinary and innovative projects.