The Head of Operations and Maintenance (O&M) at Eiffage Energía Sistemas, Francisco Javier Triguero, explains in an interview with the Director of Infonergética, Andrés Muñoz, how to ensure the optimal performance of a photovoltaic solar farm.

Triguero highlights the main tasks of the O&M department at Eiffage Energía Sistemas, which encompass Preventive, Predictive, and Corrective Maintenance. The aim is to minimise the need for Corrective Maintenance through the first two types, especially in plants constructed from 2018 onwards. In these plants, 70% of maintenance is Preventive and 30% is Corrective.

The department’s objective is to ensure the plants remain operational for the maximum possible time.

Specialised teams

Currently, at Eiffage Energía Sistemas, all preventive maintenance activities are carried out by in-house staff, except for certain services like private security and regulatory inspections, which are handled by specialist companies as required by law.

This means our company has qualified personnel in all areas: Continuous maintenance; high-voltage maintenance; solar panel cleaning; vegetation clearing and aerial thermography.

Cutting-edge technology

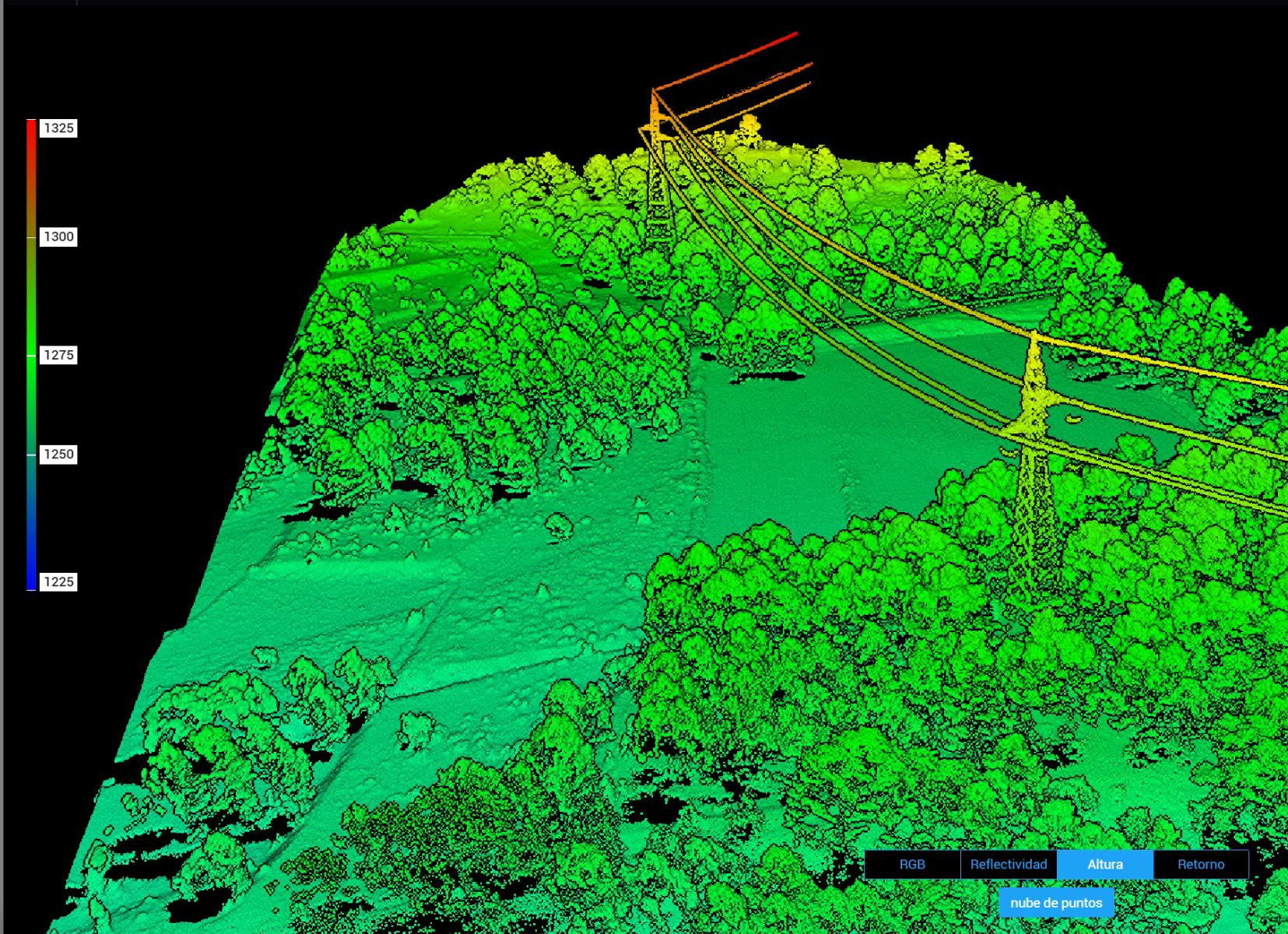

Through our drone department, utilising Artificial Intelligence, we conduct aerial thermography of all panels and provide topography services using LiDAR technology. Additionally, we have our own portal that not only collects results but can also be accessed by field technicians, allowing them to take action at any time.

As the Head of Operations and Maintenance (O&M) explains, this enables us to assist other departments such as Engineering and Construction, thereby completing the plant’s life cycle. “We offer a 360-degree, high-quality service”.

Smarter maintenance

Eiffage Energía Sistemas aims to achieve smarter maintenance through Artificial Intelligence.